Automotive Counter Shafts

Automotive Counter Shafts Specification

- Diameter

- 7 Inch (in)

- Surface

- Lubrication Type

- Usage & Applications

- Automotive Manual Transmissions

- Weight

- 11230 Grams (g)

- Features

- High Strength, Precise Tolerance, Wear Resistant

- Life Span

- Long Service Life

- Load Capacity

- 500 Kilograms (kg)

- Dimension (L*W*H)

- 14*8*7 Inch (in)

- Product Type

- Transmission Parts

- Steering Parts Type

- Other

- Transmission Parts Type

- Other

- Material

- Steel

- Size

- As per Specs

- Vehicle Type

- Japanese

- OE Number

- Available Upon Request

- Car Make

- Toyota, Nissan, Honda, Mitsubishi (Others on Request)

- Packaging

- Export-Standard/Custom

- Teeth Type

- Helical or Spur (as per application)

- Heat Treatment

- Carburized & Hardened

- Port of Dispatch

- Mumbai, India

- Manufacturing Process

- CNC Machined, Broached, Heat Treated

- Straightness Tolerance

- 0.02 mm

- OEM Services

- Available

- Corrosion Resistance

- Yes, Surface Treated

- Compatibility

- Custom Fit for Multiple Japanese Vehicle Models

- Minimum Order Quantity

- 100 Pcs

- Roundness

- 0.01 mm

Automotive Counter Shafts Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- As per requirements

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Export Worthy

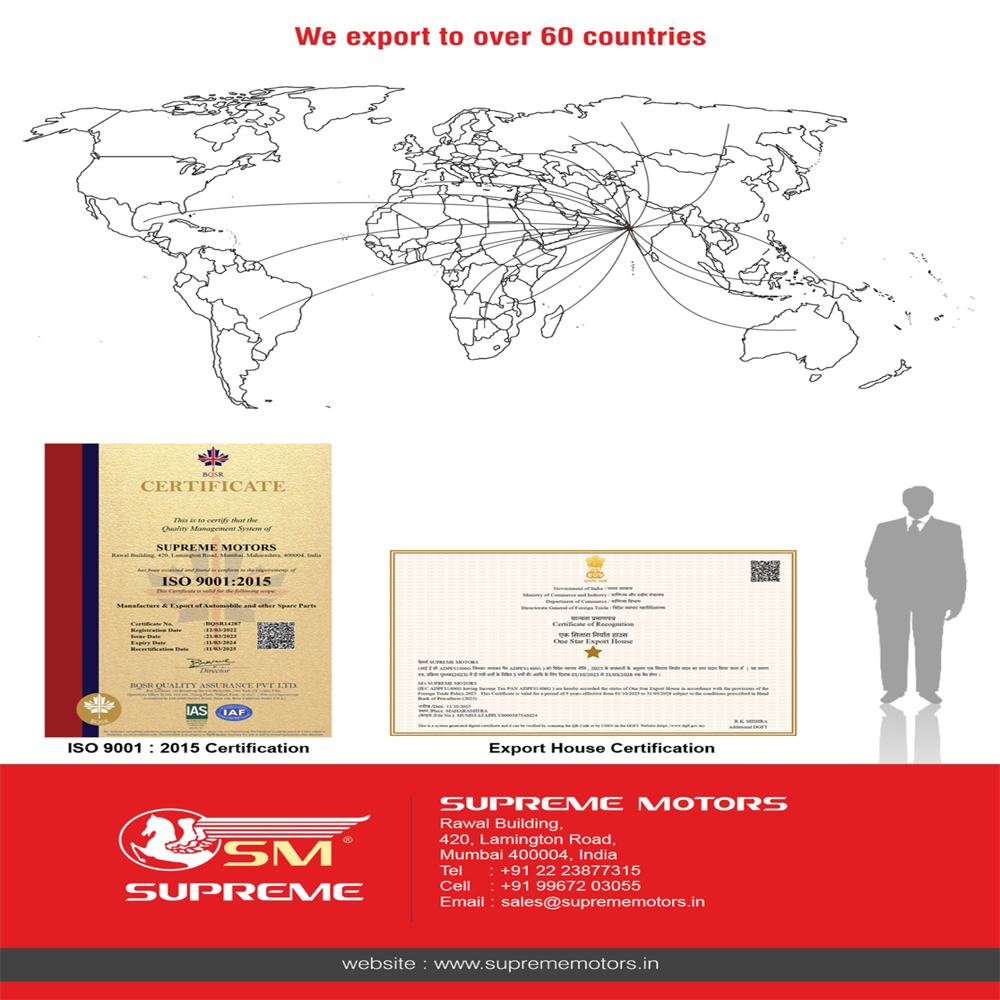

- Certifications

- ISO 9001:2015 Certified

About Automotive Counter Shafts

Mitsubishi Canter:

4D31 , FE4 - ME603214 , ME604096 , ME604030;

4D34 , 4D35 , FE8 - ME533855;

4D30 , 4D31 , FE4 - ME603213;

4D34 , FE7#P , FE8#P - ME515100;

4D34 , FE7#P , FE8#P - ME602416;

FE7 - ME530022;

Mazda T3500:

W508-17-301 ,

Tata:

250526307903

250530147901

251626307906 , 886726000034 ,

251626307906 , 886726000034 ,

Eicher:

ID201171 ,

ID201204 ,

Benz:

ME533094

Advanced Manufacturing Process

Each counter shaft is produced using state-of-the-art CNC machining and broaching techniques to ensure dimensional accuracy and superior surface finish. The parts undergo rigorous heat treatment, including carburizing and precision hardening, for enhanced wear resistance and longevity. Induction hardening and precision grinding further boost strength for demanding transmission requirements.

Custom OEM Solutions for Japanese Vehicles

We offer compatibility for multiple Japanese car models such as Toyota, Nissan, Honda, and Mitsubishi, providing OEM services to meet specific requirements. Counter shafts are tailored according to client specifications and vehicle drawings, accommodating various sizes, transmission designs, and load capacities. Dimensions and weight are model dependent, supporting maximum flexibility for automotive manufacturers and suppliers.

Export Quality Assurance and Packaging

All products are subject to strict quality controls, meeting export certification standards. Corrosion resistance and surface treatments are applied to ensure long-term protection. Shafts are packaged using export-standard or custom solutions, ensuring safe transit from Mumbai, India, to global clients. Minimum order quantity is 100 pieces, supporting bulk purchases for distributors, exporters, and service providers.

FAQs of Automotive Counter Shafts:

Q: How are the automotive counter shafts manufactured for maximum durability?

A: The shafts are CNC machined and broached from alloy or forged steel, then undergo heat treatment processes like carburizing, induction hardening, and precision grinding. This creates high strength and superior wear resistance, vital for heavy-duty manual transmission use.Q: What types of teeth are available on these counter shafts, and how is the selection determined?

A: We offer both helical and spur gear teeth, with selection based on specific transmission application requirements. This allows engineers to choose the optimal gear profile for noise reduction, load distribution, and smooth operation.Q: When can OEM customization services be requested, and what is the process?

A: OEM customization is available upon inquiry. Clients provide vehicle specifications or drawings, detailing dimensions and compatibility needs. Our engineering team then manufactures shafts to match these custom requirements, ensuring a precise fit for various Japanese car models.Q: Where are your counter shafts manufactured and shipped from?

A: All manufacturing, quality assurance, and packaging take place in India, with dispatch from Mumbai. We supply globally to distributors, exporters, manufacturers, and service providers.Q: What benefits do the precise straightness and roundness tolerances offer to automotive applications?

A: Strict straightness (0.02 mm) and roundness (0.01 mm) tolerances ensure optimal alignment, efficiency, and reduced vibration within manual transmissions. This results in smoother gear shifts and extends the service life of the transmission system.Q: How should customers lubricate the counter shafts for optimal performance?

A: Depending on the transmission design, counter shafts can be lubricated using grease or oil. Proper lubrication reduces friction, minimizes wear, and supports the long service life of the component.Q: What are the packaging standards for export, and is custom packaging available?

A: We adhere to export-standard packaging to safeguard each counter shaft during transit. Custom packaging solutions are also available upon request to meet specific logistical or branding needs.

Price 8750.0 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 30 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transmission And Gear Lever Category

Automotive Shifter Cables

Price 750.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other

Steering Parts Type : Other

Vehicle Type : Japanese

Product Type : Transmission Parts

Synchronizer Hub

Price 1125.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Steering Parts Type : Other

Vehicle Type : Japanese

Product Type : Transmission Parts

Automotive Gears

Price 2800.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Steering Parts Type : Other

Vehicle Type : Japanese

Product Type : Transmission Parts

Automotive Differential Flanges

Price 800.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Steering Parts Type : Other

Vehicle Type : Japanese

Product Type : Transmission Parts

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese